What are Concrete Fiber Additives and How Do They Work?

Concrete fiber additives significantly enhance the properties of traditional concrete, offering numerous benefits for structural integrity and sustainability. Heres an in-depth look at the advantages of adding fibers to concrete mixtures:

Enhanced Tensile Strength and Durability

Fibers like steel, glass, and synthetic materials improve tensile strength and reduce the risk of cracking, extending the lifespan of concrete structures. Eco-friendly options such as jute or recycled polyester create more durable concrete that withstands environmental and mechanical stresses.

Improved Workability

Fibers can enhance the flowability of concrete, making it easier to handle and pour. This leads to more consistent and efficient construction processes, ensuring uniform placement and reducing the likelihood of defects.

Increased Sustainability

Using bio-sourced fibers lowers the environmental impact of concrete. These fibers offer benefits such as thermal insulation, fire resistance, and reduced carbon emissions. They also align with sustainability goals, contributing to a greener construction industry.

Cost-Effectiveness

While some fiber types may be initially more expensive, the long-term benefits of reduced maintenance and extended lifespan can make fiber-reinforced concrete a cost-effective solution. The overall reduction in maintenance costs and enhanced longevity offset the initial investment.

Key Types of Fiber Additives

Concrete can benefit from various types of fiber additives, each with specific advantages:

Steel Fibers

Steel fibers provide exceptional tensile strength and crack resistance, making them ideal for high-torque applications and environments requiring extreme durability.

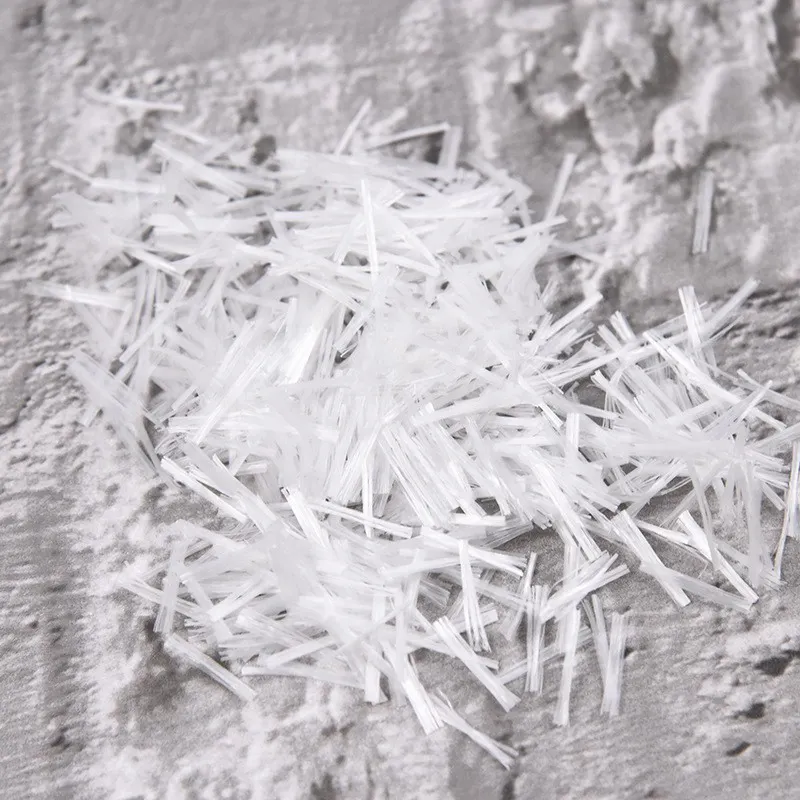

Synthetic Fibers

Synthetic fibers like polyester or polypropylene offer controlled cracking and enhanced tensile strength. They are versatile and suitable for a wide range of projects.

Natural Fibers

Natural fibers such as coconut or cotton add eco-friendly and cost-effective options, improving workability and durability. They align well with sustainability goals but may vary in performance consistency.

Mineral Fibers

Glass fibers are known for their high tensile strength and thermal insulation properties, making them suitable for specialized applications requiring enhanced fire resistance.

Hybrid Systems

Combining multiple fiber types can offer synergistic effects, improving various aspects of concrete performance, such as tensile strength, abrasion resistance, and overall sustainability.

How Fiber Additives Enhance Concrete Strength and Durability

Fiber additives significantly enhance the strength and durability of concrete by providing additional tensile strength and reducing the tendency for cracking. Synthetic fibers such as polypropylene and polyester improve workability and help manage shrinkage and thermal stresses, which are common causes of cracks in concrete structures. Steel fibers offer superior impact resistance and durability, making them invaluable for structures exposed to harsh environmental conditions. Natural fibers like jute provide an eco-friendly and cost-effective alternative, contributing to tensile strength and crack reduction while supporting sustainability goals.

Effective Use of Concrete Fiber Additives

The effective use of fiber additives involves careful considerations to ensure both performance and sustainability. Proper distribution of fibers is achieved through wet mixing during the initial stages of concrete preparation. Different types of fibers, such as polypropylene, steel, and glass, each offer unique benefits, making the selection process dependent on the specific project requirements, including environmental conditions and load requirements.

Testing protocols are crucial for verifying fiber performance. Key tests include flexural and tensile strength assessments, water permeability, and durability evaluations. Sustainable practices, such as the use of recycled fibers, are increasingly important, balancing environmental impact with performance standards.

The industry is exploring emerging fiber technologies like carbon and bio-based fibers, but consistent performance remains a challenge. Quality control measures and standardized procedures ensure that these fibers meet necessary standards, contributing to the overall effectiveness and sustainability of concrete construction projects.

Cost Effectiveness and Environmental Impact of Fiber Additives

Fiber additives in concrete have gained significant traction for their cost-effective and environmentally beneficial characteristics. By reducing the need for additional metal reinforcements, they decrease overall project costs and minimize waste and energy consumption during production.

For instance, incorporating recycled glass fibers not only aligns with sustainability goals by lowering the carbon footprint and water usage but also provides a cost-effective alternative due to lower production costs and reduced long-term maintenance expenses. Projects often consider regulatory compliance, cost-benefit analysis, sustainability impact, technical performance, and supply chain reliability when evaluating the use of recycled glass fibers.

Challenges such as ensuring consistent quality of the recycled glass supply, managing initial higher costs, and preventing aggregation during mixing are effectively addressed through robust partnerships with suppliers, thorough cost-benefit analyses, and advanced mixing techniques. These strategies have successfully facilitated the implementation of fiber additives, making them a preferred choice in modern construction practices.

-

-

5.1Steel Fibers

-

+86 133 5816 4686

13358164686@163.com

Contact: COCO

Tel: +86 133 5816 4686

WhatsApp: +86 138 0714 0719

Add:

33 Huayuan Street, Wujin District, Changzhou City, Jiangsu Province