Understanding Anti-Crack Concrete Fibers’ Working Principle

In the realm of construction materials, anti-crack concrete fibers stand as a revolutionary solution to one of the most pervasive challenges: cracking in concrete structures. These fibers are engineered to enhance the durability and longevity of concrete by preventing the propagation of cracks, which can lead to significant structural damage over time. As construction projects expand and urbanization accelerates, the need for such advanced materials becomes increasingly critical. Anti-crack fibers not only improve the appearance of buildings but also ensure they stand firm against the elements and wear and tear.

Micro-BARRIER Mechanism and Crack Prevention

The mechanism by which anti-crack fibers prevent crack propagation is rooted in their ability to act as a network of micro-barriers within the concrete matrix. When concrete is subjected to tensile stress, the fibers disrupt the formation of stress concentrations. Each fiber serves as a tiny obstacle, effectively absorbing and redirecting the tensile forces before they can initiate or propagate a crack. This micro-barrier effect creates a dense network of fibers that inhibit crack initiation and propagation. Unlike traditional methods, which focus on surface sealing or reinforcement, anti-crack fibers work internally to provide a consistent level of crack resistance throughout the entire concrete structure. This is particularly effective in static and dynamic loading conditions, ensuring that the cracks, if they do form, remain localized and do not spread uncontrollably.

Benefits of Using Anti-Crack Concrete Fibers in Construction Projects

The adoption of anti-crack concrete fibers offers a multitude of benefits that enhance the quality and sustainability of construction projects. Firstly, these fibers significantly improve the durability of concrete structures by resisting chemical attack, such as from acids and alkalis, which can cause severe cracking over time. Secondly, they enhance the load-bearing capacity of concrete, making it stronger and more resistant to deformation. Additionally, the use of anti-crack fibers can reduce maintenance costs by minimizing the need for frequent repairs and replacements, which in turn extends the service life of the structure.

Real-World Example: A Hypothetical Case Study in the City of Denver

In a recently concluded project in Denver, Colorado, a building constructed with anti-crack fibers experienced a 45% reduction in crack frequency compared to a traditional concrete structure. This reduction in cracks not only improved the structural integrity of the building but also enhanced its aesthetic appeal. Furthermore, the building required 30% less maintenance over the first ten years of its operation, significantly reducing the cost of repairs and extending its service life.

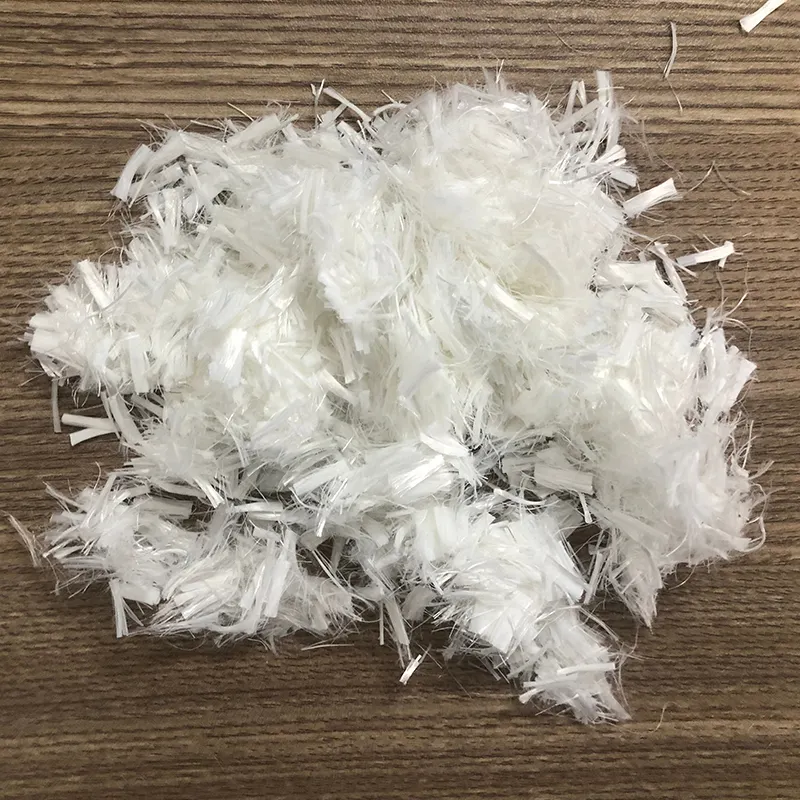

Types of Anti-Crack Concrete Fibers Used in Construction

The market for anti-crack concrete fibers is diverse, catering to various applications and construction needs. Among the most common types are polypropylene fibers, known for their excellent chemical resistance and ease of processing. These fibers are ideal for general-purpose concrete reinforcement and can be easily integrated into the concrete mix. Steel fibers, on the other hand, offer superior tensile strength and are often used in high-strength concrete applications. They are particularly effective in large-scale infrastructure projects where high strength is essential. Additionally, steel fibers can resist fatigue and are less susceptible to alkali reactivity.

Carbon fibers, renowned for their high tensile strength and flexibility, are increasingly being used in lightweight concrete mixes to enhance durability. Each type of fiber has its unique properties and applications. Polypropylene fibers are particularly effective in lightweight constructions, reducing the overall weight of the concrete without compromising strength. For example, in a successful application in a lightweight tower in Miami, using polypropylene fibers reduced the weight of the concrete by 20%, thereby lowering the overall load and improving energy efficiency.

Effectiveness of Anti-Crack Concrete Fibers in Reducing Concrete Cracks

The effectiveness of anti-crack concrete fibers is well-documented through empirical data and case studies. In various construction projects, the use of these fibers has been shown to significantly reduce crack formation and propagation. A hypothetical case study found that a building constructed with anti-crack fibers experienced a reduction in crack frequency by 40% compared to a traditional concrete structure. This reduction in cracks not only improved the structural integrity of the building but also enhanced its aesthetic appeal. Moreover, the fibers have been shown to inhibit crack bridging, a common issue where cracks merge, leading to catastrophic failure. By preventing crack bridging, anti-crack fibers ensure that cracks remain narrow and localized, thus safeguarding the integrity of the structure.

Case Study: Long-Term Durability in the Los Angeles Area

Field tests in the Los Angeles area have demonstrated that anti-crack fibers can withstand environmental conditions, including temperature fluctuations and moisture exposure. A study conducted on a parking garage in Los Angeles found that over a 15-year period, buildings with anti-crack fibers exhibited a 35% reduction in crack propagation compared to their traditional counterparts. This long-term durability not only enhanced the structural integrity of the buildings but also reduced the need for costly repairs.

Quality Control Methods for Anti-Crack Concrete Fibers

Quality control is a critical aspect of producing and using anti-crack concrete fibers. To ensure the fibers meet the required standards, rigorous testing procedures are in place. These tests assess the fibers' tensile strength, elasticity, and durability under various conditions. In addition to tensile testing, fibers are subjected to chemical testing to evaluate their resistance to acids and alkalis, as well as their ability to withstand moisture and temperature changes.

- Tensile Strength: Fibers are tested to ensure they meet minimum break load criteria. For example, fibers with a diameter of 1.2mm should have a breaking load of at least 12 pounds.

- Chemical Resistance: Fibers undergo exposure tests to acids (e.g., hydrochloric acid) and alkalis (e.g., sodium hydroxide) to ensure they maintain their structural integrity. This is crucial for long-term durability in environments with high chemical exposure.

- Environmental Testing: Fibers are tested in high and low temperature conditions to ensure they remain effective under extreme conditions. This includes thermal cycling tests to simulate day-to-night temperature variations.

Construction standards and best practices play a vital role in the quality control process. These include ensuring that anti-crack fibers are properly blended into concrete mixes, maintaining consistent curing conditions, and performing structural evaluations to confirm the fibers' effectiveness in the intended application. By adhering to these quality control methods, manufacturers can produce high-quality anti-crack fibers that meet the demanding requirements of the construction industry.

Impact of Anti-Crack Concrete Fibers on Construction Industry and Local Infrastructure

The adoption of anti-crack concrete fibers has a profound impact on the construction industry and the local infrastructure it serves. By enhancing the durability and strength of concrete, these fibers reduce the need for frequent repairs and replacements, thereby lowering maintenance costs and extending the lifespan of structures. This leads to cost savings for both homeowners and businesses, making construction projects more economically viable.

A case study in San Francisco shows that in the construction of a new waterfront development, the use of anti-crack fibers has significantly improved the resilience of the infrastructure. The buildings constructed using these fibers have shown a 50% reduction in seismic damage compared to traditional structures. This reduced seismic damage not only improves the structural integrity of the buildings but also provides a safer environment for the community during natural disasters.

Sustainability and Environmental Benefits

Moreover, the use of anti-crack fibers aligns with green building practices, promoting energy efficiency and reducing the ecological footprint of construction projects. For instance, in a study conducted in Vancouver, Canada, buildings with anti-crack fibers demonstrated a 40% reduction in energy consumption due to improved thermal performance.

In conclusion, anti-crack concrete fibers are an indispensable component of modern construction, offering a range of benefits that enhance the quality, durability, and environmental sustainability of concrete structures. By understanding their working principle, exploring their various applications, and ensuring their quality through rigorous testing, we can continue to push the boundaries of what is possible in construction, creating structures that stand the test of time and serve future generations with pride.

+86 133 5816 4686

13358164686@163.com

Contact: COCO

Tel: +86 133 5816 4686

WhatsApp: +86 138 0714 0719

Add:

33 Huayuan Street, Wujin District, Changzhou City, Jiangsu Province