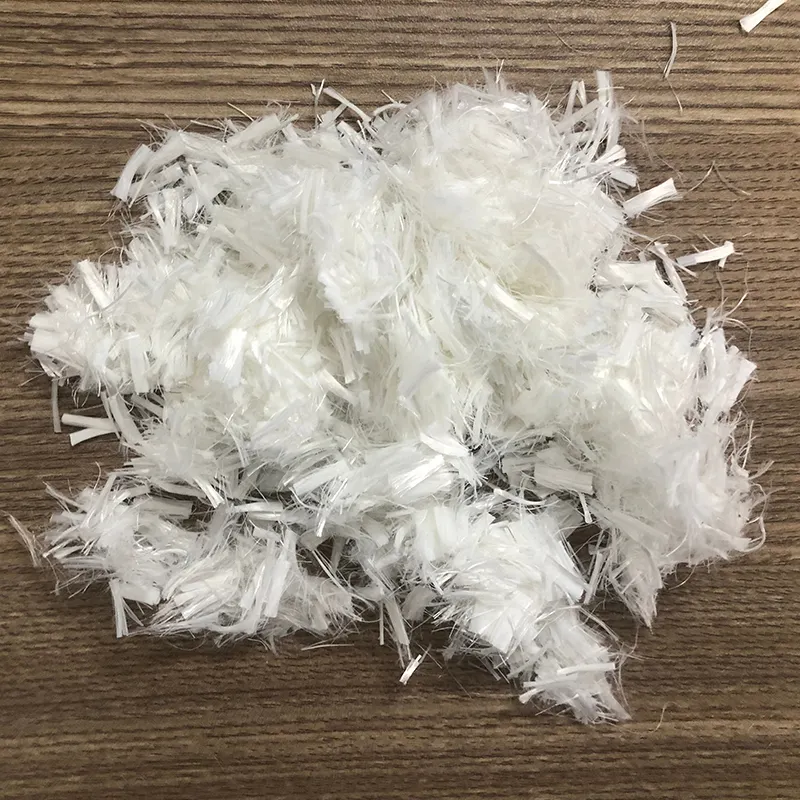

Optimal Glass Fiber Anti-Crack for Projects

Anti-crack glass fibers are a game-changer when it comes to enhancing the durability and longevity of construction materials. These fibers are designed to prevent cracking by evenly distributing stress across the matrix, making them ideal for high-traffic areas like sidewalks and roads, as well as large-scale infrastructure projects. By embedding these fibers into concrete and other materials during the manufacturing process, developers can significantly reduce the likelihood of cracking and extend the life of their structures.

Latest Advancements in Anti-Crack Glass Fiber Technology

Recent technological breakthroughs have improved the performance and usability of anti-crack glass fibers. Ultra-high-performance fibers can withstand extreme temperatures and chemical treatments, making them perfect for harsh conditions. Biodegradable glass fibers are a sustainable alternative, releasing their reinforcing properties over time and proving ideal for green building projects. Advanced manufacturing techniques ensure uniformity and consistency, optimizing the fibers performance in various applications.

Real-World Applications and Case Studies

Glass fibers have been successfully integrated into numerous construction projects. For instance, a newly constructed highway bridge in a major city recently replaced traditional concrete with anti-crack glass fibers. This resulted in a structure that has withstood years of aggressive weathering and heavy traffic, meeting the required standards for durability and reducing frequent repairs. Another example is a commercial building in a high-crime area, where anti-crack glass fibers in the exterior significantly reduced cracking damage caused by criminal activity, enhancing both the aesthetic and structural integrity of the building.

Environmental Impact and Sustainability

The use of anti-crack glass fibers has a significant positive environmental impact. They help conserve resources and reduce waste by extending the lifespan of construction materials. Biodegradable fibers, in particular, offer a sustainable solution by breaking down naturally over time, reducing long-term contamination and minimizing the environmental impact of construction materials.

Challenges and Future Directions

Despite their benefits, anti-crack glass fibers face several challenges. The high production costs make them less accessible for smaller construction projects. Additionally, the complexity of manufacturing processes can result in limited supply. Public awareness and acceptance of these fibers are also critical but often lacking. Future research should focus on cost-effective production methods and innovative applications to better address these gaps and enhance their adoption.

How Effective Are Glass Fibers in Preventing Cracks in Concrete?

Experimental studies and theoretical models have shown that anti-crack glass fibers significantly reduce the number of cracks in concrete under various loading conditions. They improve impact resistance, making the concrete more capable of withstanding impacts and vibrations that can lead to cracking. Optimizing the orientation, spacing, and volume fraction of the fibers can further enhance their performance.

Best Practices for Integrating Anti-Crack Glass Fibers into Building Designs

- Consult with Specialists: Work closely with materials scientists, engineers, and architects to ensure the optimal integration of glass fibers.

- Test for Durability: Conduct accelerated aging tests and environmental testing to ensure the fibers perform as expected in specific conditions.

- Consider Fiber Placement: Ensure uniform placement of fibers to avoid weak spots in the material.

- Monitor Performance: Closely monitor the performance of glass fibers after construction to ensure they are functioning as intended.

- Sustainability Considerations: Use biodegradable or recycled glass fibers to minimize the environmental impact.

By following these best practices, construction professionals can maximize the benefits of anti-crack glass fibers, creating structures that are not only durable and sustainable but also resistant to cracking.

+86 133 5816 4686

13358164686@163.com

Contact: COCO

Tel: +86 133 5816 4686

WhatsApp: +86 138 0714 0719

Add:

33 Huayuan Street, Wujin District, Changzhou City, Jiangsu Province