Optimal Compliance for Anti-Crack Fiber Usage

In the world of construction and materials science, safety and durability are paramount. From the tallest skyscrapers to the most durable bridges, materials play a critical role in ensuring the integrity of our infrastructure. However, even the best materials can fail, leading to costly repairs, safety hazards, and project delays. Thats where anti-crack fibers come into play. These advanced materials are revolutionizing the construction industry by preventing cracks from forming or spreading, thereby enhancing the overall safety and longevity of structures.

What Are Anti-Crack Fibers and Their Applications in Industrial Standards?

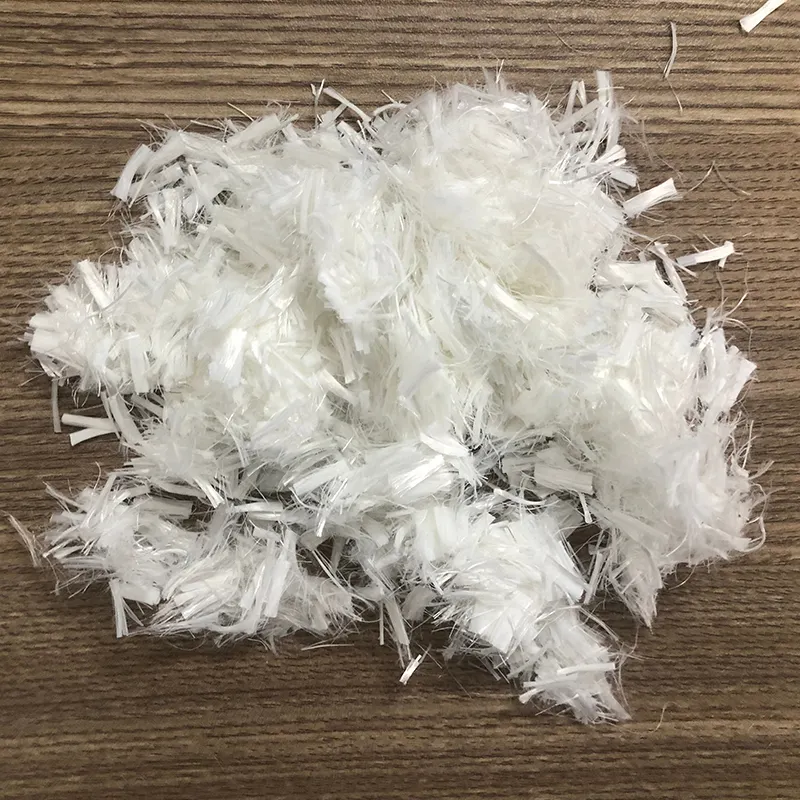

Anti-crack fibers are a type of advanced composite material designed to resist cracking and delamination under stress. Unlike traditional materials prone to brittle failures, anti-crack fibers distribute stress evenly, preventing weak points that lead to cracks. They are widely used in various industries, including construction, automotive, aerospace, and manufacturing. In the context of construction, anti-crack fibers are particularly valuable in materials like prepregs, which are used to manufacture carbon fiber-reinforced polymers (CFRP). These materials are increasingly being adopted for their superior durability and weightlessness, making them ideal for high-stress environments such as bridges, towers, and aircraft.

Expanded Explanation:

Anti-crack fibers are engineered to enhance the integrity of materials by resisting the formation and propagation of cracks. They function by distributing stress evenly across the material, thereby preventing the accumulation of strain at specific points that could lead to cracking. This stress distribution ensures that materials remain intact and perform optimally under various conditions. For instance, in the construction industry, anti-crack fibers are integral to materials like carbon fiber-reinforced polymers (CFRP). These advanced composites are favored in high-stress applications such as bridge construction, tower reinforcement, and aircraft components due to their superior durability and lightweight properties.

Benefits of Anti-Crack Fibers in Construction and Other Industries

Enhanced Durability

Anti-crack fibers distribute stress evenly, significantly reducing the likelihood of weak points forming. This uniform stress distribution prevents materials from developing cracks, which can lead to catastrophic failures. For instance, in bridge construction, anti-crack fibers can prevent fatigue cracks in steel beams, ensuring the bridge remains structurally sound under various environmental conditions. The result is a more durable and resilient structure that can withstand prolonged use and harsh weather conditions.

Reduced Maintenance Costs

By preventing cracks and delamination, anti-crack fibers significantly reduce the need for costly repairs and replacements. Traditional materials often require periodic maintenance to address cracks and other structural issues. The use of anti-crack fibers extends the lifespan of materials, thereby lowering operational costs. For example, incorporating anti-crack fibers into bridge decks can prevent the need for frequent patching, leading to substantial savings over time.

Increased Safety for Workers and Passengers

Structures built with anti-crack fibers are inherently safer. They reduce the risk of injuries caused by vibrations, drops, or other sources of stress. For instance, in the automotive industry, anti-crack fibers in the frame and body panels can absorb and dissipate energy more effectively, reducing the risk of accidents and injuries. In construction, workers face the challenge of repetitive strain and improper repairs due to cracks. By using anti-crack fibers, the risk of these issues can be significantly reduced, ensuring a safer working environment.

Improved Longevity

Anti-crack fibers ensure that materials can withstand extreme conditions, such as temperature fluctuations, impacts, and environmental stressors. For example, in aerospace applications, anti-crack fibers ensure that components like aircraft wings and fuselages can handle the rigors of flight without developing cracks. This improved longevity not only extends the life of the materials but also reduces the frequency of maintenance and repairs.

Expanded Explanation:

Enhanced Durability

Imagine a skyscraper that not only looks impressive but also stands the test of time. Anti-crack fibers distribute stress evenly across the materials used, preventing weak points that can lead to cracks. This means that the building can withstand various weather conditions, heavy loads, and other stresses without showing signs of wear. Consequently, the structure remains intact for a much longer period, reducing the need for frequent repairs and maintenance.

Reduced Maintenance Costs

Traditional materials often require regular inspections and maintenance to address cracks and other structural issues. This can be time-consuming and expensive. In contrast, anti-crack fibers ensure that materials remain strong and intact, reducing the need for repairs. For instance, bridge decks made with these fibers save maintenance costs by preventing cracks and prolonging the lifespan of the bridge. This not only saves money but also ensures that the infrastructure remains safe and functional for years to come.

Increased Safety for Workers and Passengers

In the construction and automotive industries, safety is paramount. Anti-crack fibers play a crucial role in enhancing safety. They prevent the formation of cracks, which can sometimes lead to failures in critical structures. For example, in the automotive industry, frames and body panels made with these fibers can absorb and dissipate energy more effectively during an impact, reducing the risk of accidents and injuries. Similarly, in construction, workers are less likely to experience repetitive strain or improper repairs due to cracks. This ensures a safer working environment and reduces the risk of workplace accidents.

Improved Longevity

Materials that can withstand extreme conditions are invaluable, especially in industries like aerospace. Anti-crack fibers ensure that components such as aircraft wings and fuselages can handle the rigors of flight without developing cracks. This enhanced longevity not only extends the life of the components but also reduces the frequency of maintenance and repairs. For instance, airplanes made with anti-crack fibers can fly for thousands of hours without needing major repairs, saving airlines substantial costs and ensuring safe and reliable air travel.

Regulatory Oversight and Compliance Guidelines for Anti-Crack Fibers

Regulatory oversight is essential to ensure that anti-crack fibers are used responsibly and in compliance with safety standards. Different industries and regions have their own regulatory frameworks, but many share common guidelines for material certification and application.

For instance, in construction, the use of anti-crack fibers must comply with codes and standards such as the International Building Code (IBC) and the National Institute of Structural Engineering (NISE). These documents outline the minimum requirements for materials, including the need for anti-crack fibers in specific applications.

Similarly, in the automotive industry, standards like the Society of Automotive Engineers (SAE) J647 and ISO 26262 dictate the use of anti-crack fibers in components exposed to high stress, such as bumpers, undercarriage, and frames. These standards ensure that vehicles are safer and more durable.

In addition to compliance, manufacturers must follow strict production and testing protocols to ensure that anti-crack fibers meet the required specifications. Testing includes evaluating tensile strength, elongation, and resistance to environmental factors like moisture and temperature. For example, materials must be tested under simulated weather conditions to ensure they can withstand prolonged exposure to UV light and changes in temperature.

Real-World Examples of Anti-Crack Fiber Usage in Construction

Real-world examples of anti-crack fibers in action highlight their transformative impact on construction projects.

The Golden Gate Bridge: A Case Study

One notable case is the use of anti-crack fibers in the construction of the Golden Gate Bridge in San Francisco. The bridge spans over 1,275 meters and is subjected to intense stress from vehicles, wind, and weather conditions. By incorporating anti-crack fibers into its steel beams, engineers were able to significantly reduce the risk of fatigue cracks, ensuring the bridges structural integrity for decades.

The Burj Khalifa: Engineering a Tall Triumph

Another example is the use of anti-crack fibers in the construction of the Burj Khalifa, the tallest building in the world. The building relies on advanced composite materials, including anti-crack fibers, to withstand the immense forces of wind and earthquakes. These fibers were critical in preventing cracks that could have led to catastrophic failures.

New Zealand Bridge Retrofit: A Cost-Effective Solution

In a more recent project, a bridge in New Zealand experienced extensive damage due to repeated stress and cracking. After retrofitting the bridge with anti-crack fibers, the structure has returned to its original condition, saving millions in repair costs and ensuring long-term safety for users.

Expanded Explanation:

Real-World Examples of Anti-Crack Fiber Usage in Construction

Real-world examples showcase the immense value of anti-crack fibers in enhancing the safety, durability, and longevity of structures. One prime example is the Golden Gate Bridge in San Francisco. Spanning over 1,275 meters, this iconic bridge is subjected to significant stress from vehicles, wind, and weather. Incorporating anti-crack fibers into its steel beams has significantly reduced the risk of fatigue cracks. These fibers ensure that the bridge's structural integrity remains intact for decades, providing a safe and reliable transportation link for millions of commuters.

The Burj Khalifa, the tallest building in the world, is another testament to the effectiveness of anti-crack fibers. The structure relies on advanced composite materials that include these fibers to withstand the extreme forces of wind and earthquakes. Anti-crack fibers in the buildings components are critical in preventing cracks, ensuring the structure can handle the rigors of high-stress environments. This has not only extended the building's lifespan but also guaranteed its safety and reliability, allowing it to stand as a symbol of engineering prowess.

A more recent success story comes from a bridge in New Zealand. This bridge suffered extensive damage due to repeated stress and cracking. Traditional repair methods proved insufficient, leading to significant costs and safety concerns. However, after retrofitting the bridge with anti-crack fibers, the structure was able to return to its original condition. The savings in repair costs and the long-term safety benefits for users have been substantial. This case study demonstrates the practical and effective application of anti-crack fibers in real-world scenarios, where their impact is most visible.

The Impact of Anti-Crack Fibers on Job Safety and Security

While anti-crack fibers primarily benefit manufacturers and builders, their impact on job safety and security cannot be overstated.

Preventing Workplace Injuries

By using anti-crack fibers, workers are less likely to experience injuries caused by repetitive strain or improper repairs. For instance, in the construction industry, workers often face repetitive movements and improper repairs due to cracks. Anti-crack fibers ensure that structures are more robust, reducing the risk of worker injuries. In bridge construction, workers face the risk of falling or being injured by loose or unstable components. By using anti-crack fibers in steel beams and other materials, the risk of such accidents is significantly reduced, enhancing worker safety.

Ensuring Product Safety

The use of anti-crack fibers ensures that the products we use every day, from bridges to airplanes, are safe for their intended purpose. This builds trust in manufacturers and end-users, fostering a culture of safety and reliability. Anti-crack fibers in automotive components, for example, can absorb more energy in a collision, enhancing the safety of vehicles. This not only builds trust among consumers but also ensures that manufacturers are committed to high standards of safety.

Reducing Workplace Accidents

Cracks and delamination in materials can lead to falls, trips, and other accidents. By preventing these issues, anti-crack fibers help create safer workplaces. For construction workers, this means fewer trips and falls, reducing the overall risk of workplace accidents. In the automotive industry, anti-crack fibers in components like bumpers and undercarriage can improve vehicle performance during collisions, further ensuring safety for passengers.

Enhancing Employee Morale

When workers know their jobs are safe and their products are reliable, they are more likely to feel secure and motivated. This contributes to a positive workplace culture and ultimately increases productivity and satisfaction. For instance, in construction, workers who are not constantly worried about unsafe working conditions can focus more on their tasks and perform at a higher level. This fosters a culture of safety and reliability, ensuring that the company remains successful and competitive.

Expanded Explanation

The positive impact of anti-crack fibers extends beyond the structural integrity of buildings and bridges to the safety and well-being of workers. In the construction industry, workers are at risk of repetitive strain injuries and improper repairs due to cracks, leading to accidents and injuries. Anti-crack fibers ensure that materials are more robust and less prone to cracking, reducing the risk of workplace injuries. For example, in bridge construction, workers face the risk of falling or being injured by loose or unstable components. By using anti-crack fibers in steel beams and other materials, the risk of such accidents is significantly reduced, enhancing worker safety.

In the automotive industry, anti-crack fibers play a crucial role in ensuring product safety. When components made with these fibers are used in vehicles, they can absorb more energy in collisions, reducing the risk of injuries to passengers. This not only builds trust among consumers but also ensures that manufacturers are committed to high standards of safety. For instance, in bumpers and body panels, anti-crack fibers can significantly improve the vehicle's ability to handle impacts, ensuring that passengers remain safe during accidents.

In the construction industry, reducing the risk of workplace injuries is crucial. Anti-crack fibers ensure that materials are robust, reducing the need for dangerous repairs and maintenance. This not only enhances worker safety but also improves job satisfaction and productivity. For example, in the repair and maintenance of structures, cracks can cause workers to perform dangerous tasks, such as climbing unstable ladders. By using anti-crack fibers in steel beams and other materials, the risk of such accidents is significantly reduced, ensuring a safer working environment.

In addition to reducing the risk of accidents, anti-crack fibers enhance employee morale. When workers know that their jobs are safe and the products they work on are reliable, they are more likely to feel secure and motivated. This contributes to a positive workplace culture, where employees are more engaged and productive. For instance, in construction, workers who are not constantly worried about unsafe working conditions can focus more on their tasks and perform at a higher level. This fosters a culture of safety and reliability, ensuring that the company remains successful and competitive.

Conclusion

Anti-crack fibers are a game-changer in the construction and manufacturing industries. They not only enhance the durability and longevity of materials but also ensure job safety and security. By adhering to industrial standards and incorporating anti-crack fibers into projects, companies can meet compliance requirements, improve their reputation, and deliver high-quality products for their customers.

Expanded Conclusion

In conclusion, anti-crack fibers are revolutionizing the construction and manufacturing industries by enhancing the durability and longevity of materials, ensuring job safety and security, and improving overall product reliability. These advanced composite materials are designed to resist cracking and delamination, thereby preventing the formation of weak points that can lead to failures. By incorporating anti-crack fibers into projects, companies can meet compliance requirements and ensure that their materials meet safety and performance standards. For instance, in the construction industry, anti-crack fibers reduce the risk of fatigue cracks in steel beams, ensuring that structures remain structurally sound under various environmental conditions. Similarly, in the automotive and aerospace industries, these fibers ensure that components like bumpers, undercarriage, and aircraft wings are more durable and resistant to stresses.

The positive impact of anti-crack fibers extends beyond the structural integrity of buildings and bridges to the safety and well-being of workers. In the construction industry, reducing the risk of workplace injuries is crucial. Anti-crack fibers ensure that materials are robust and less prone to cracking, reducing the risk of workplace injuries. In the automotive and aerospace industries, anti-crack fibers play a critical role in ensuring product safety. They can absorb more energy in collisions, enhancing the safety of vehicles and aircraft.

Incorporating anti-crack fibers into projects is not only beneficial for manufacturers and builders but also ensures that the products we use every day are safe and reliable. By adhering to industrial standards and utilizing these advanced materials, companies can deliver high-quality products that meet the demands of safety and reliability, fostering a culture of trust and dependability.

Call to Action:

Incorporate anti-crack fibers into your next project to ensure compliance with safety standards and enhance job security. By adopting these advanced materials, you can not only improve the durability of your products but also contribute to a safer and more sustainable future. Contact us today to learn more about how anti-crack fibers can revolutionize your operations!

+86 133 5816 4686

13358164686@163.com

Contact: COCO

Tel: +86 133 5816 4686

WhatsApp: +86 138 0714 0719

Add:

33 Huayuan Street, Wujin District, Changzhou City, Jiangsu Province