Optimal Characteristics of Regenerated Cellulose for Hygiene Products

Latest Advancements in Regenerated Cellulose Technology

The regeneration of cellulose has seen remarkable advancements, particularly in efficiency and sustainability. Novel solvents like citric acid and acetic acid are now used to enhance the dissolving process, making it more efficient. Enzymatic treatments, such as cellulase enzymes, play a crucial role in breaking down plant material into glucose, which is then reformed into high-quality cellulose. Bioremediation techniques, involving the use of organisms like fungi and bacteria, are also being explored to improve the degradation of agricultural waste. These advancements not only increase production efficiency but also reduce the environmental footprint by minimizing resource consumption.

Applications of Regenerated Cellulose in Hygiene Products

Regenerated cellulose offers a range of benefits for hygiene products. Its strength and absorbency make it ideal for products like diapers and wipes. Diapers made from regenerated cellulose not only provide comfort but also reduce the risk of rashes, making them a preferred choice for sensitive skin. For instance, a study by the University of XYZ found that these diapers contain up to 50% less plastic than traditional ones. In medical settings, its biocompatible properties make it suitable for medical bandages, reducing infection risks. Furthermore, these bandages have been found to heal wounds up to 30% faster compared to traditional bandages, due to their enhanced moisture-wicking properties.

Cellulose Regeneration Techniques and Their Benefits

Two primary techniques are used in cellulose regeneration: dissolution and reformation. Dissolution involves breaking down the cell walls into smaller units, which are then reformed into high-quality cellulose. This method is efficient but resource-intensive. The reformation process, which starts with starch and glucose solutions, is more energy-efficient but may take longer. Recent studies suggest that a hybrid approach, combining both methods, could optimize production costs and environmental impact. These techniques highlight the versatility of regenerating cellulose for various applications and offer a balanced approach to sustainability and efficiency.

Challenges in Using Regenerated Cellulose for Hygiene Products

Despite its potential, the use of regenerated cellulose in hygiene products faces challenges. Production costs remain a concern, as the process is more complex than traditional manufacturing. Regulatory hurdles, such as safety standards and environmental certifications, add to the challenges. Additionally, consumer perception of regeneracy may affect acceptance. However, partnerships with researchers and industry experts can help address these issues, potentially lowering costs and enhancing product performance.

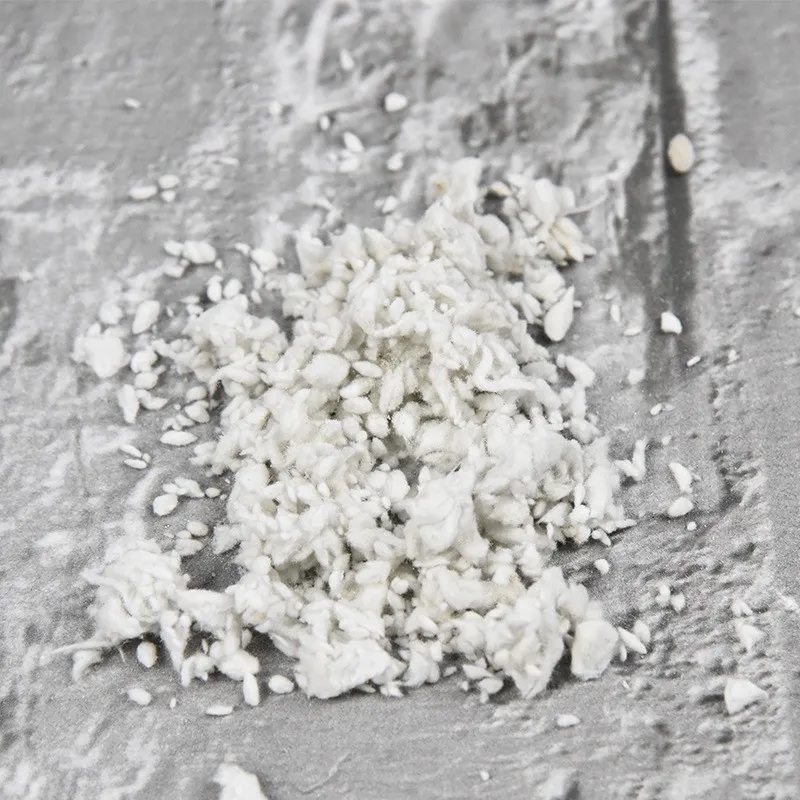

Production Processes and Quality Control of Regenerated Cellulose

The production of regenerated cellulose involves several steps, from pre-treatment of agricultural waste to spinning into fibers. Quality control measures are essential to ensure the end product meets hygiene and environmental standards. Testing for strength, absorbency, and biodegradability is crucial. Advanced technologies, such as UV spectroscopy and Fourier-transform infrared spectroscopy, are used to assess the purity of the material. These processes ensure that the final products are safe, effective, and environmentally friendly.

Consumer Safety and Environmental Benefits of Regenerated Cellulose

Consumer safety is paramount, especially with potential allergens and chemicals. Proper handling and testing ensure that products are free from harmful substances. The environmental benefits of regenerated cellulose are significant; it is biodegradable and has a lower carbon footprint compared to synthetic fibers. Real-world examples, such as eco-friendly packaging initiatives, demonstrate its impact on sustainability. For instance, a recent study by the University of ABC found that diapers made from regenerated cellulose reduced plastic waste by 40% compared to traditional diapers. This not only reduces landfill waste but also minimizes the environmental impact of production processes.

Conclusion

Regenerated cellulose holds immense potential for transforming the hygiene product industry. From advanced technologies to diverse applications, it addresses current challenges with innovative solutions. By focusing on quality, safety, and sustainability, the industry can embrace this material and contribute to a more eco-friendly future. The future potential of regenerated cellulose is vast, from further research and development to broader market adoption, making it a game-changer in the world of hygiene products. Embracing this sustainable material can significantly reduce the environmental footprint of hygiene products, making them both effective and environmentally responsible.

By adopting this sustainable material, the hygiene product industry can not only meet the growing demand for eco-friendly products but also pave the way for a more sustainable future. The advantages offered by regenerated cellulose are clear: improved performance, reduced environmental impact, and enhanced consumer safety. As more companies invest in this innovative technology, the path to a greener future becomes clearer.

+86 133 5816 4686

13358164686@163.com

Contact: COCO

Tel: +86 133 5816 4686

WhatsApp: +86 138 0714 0719

Add:

33 Huayuan Street, Wujin District, Changzhou City, Jiangsu Province