Manufacturer's Insights on Sustainable Cellulose Fiber Production

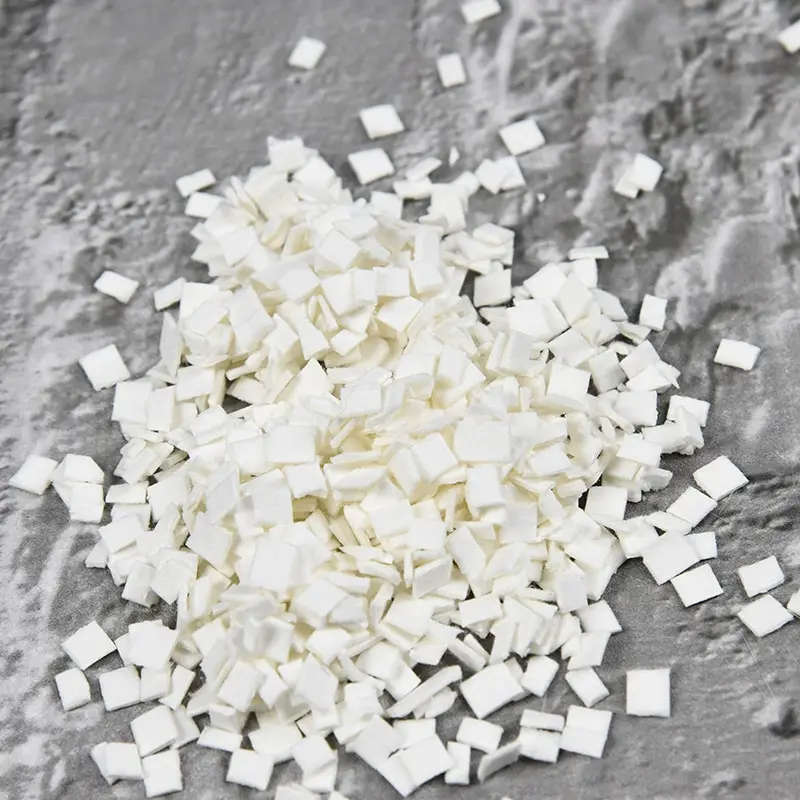

Cellulose fiber is a versatile and widely used material in various sectors, from textiles and packaging to construction and furniture. Derived from renewable sources like trees, crops, and agricultural waste, it offers a more sustainable alternative to non-renewable materials. However, the environmental impact of cellulose fiber production remains a significant concern.

One of the primary environmental challenges is the high water consumption associated with cultivating and harvesting cellulose fibers. Large-scale operations often require vast amounts of water, sourced from rivers, lakes, or deserts. This can have a detrimental effect on local ecosystems, leading to water scarcity issues and harming biodiversity. Additionally, deforestation for cellulose crops can result in significant habitat disruption and loss of biodiversity.

Energy consumption is another major issue in cellulose fiber production. The processing involves multiple energy-intensive steps, such as drying, sorting, and manufacturing. While some processes are more energy-efficient than others, the overall energy footprint remains a significant concern. Reducing this footprint is crucial for achieving sustainable production.

Despite these challenges, the growing interest in sustainability has driven innovation in the cellulose fiber industry. Manufacturers are now adopting a range of sustainable practices and technologies to mitigate environmental impacts.

Sustainable Practices and Innovations in Cellulose Fiber Production

To address these environmental challenges, manufacturers are increasingly adopting sustainable practices and innovations such as the use of alternative renewable sources and energy-efficient technologies.

Alternative Renewable Sources:

Manufacturers are exploring agricultural waste, such as crop residues and manure, to produce cellulose fibers. This approach not only reduces the need for deforestation but also promotes the use of otherwise waste materials. By converting these waste products into valuable resources, manufacturers can significantly decrease their environmental impact.

Water and Energy Efficiency:

Many companies are implementing water-saving techniques, such as advanced irrigation systems and rainwater harvesting, to reduce water consumption. Additionally, energy-efficient technologies like solar-powered drying systems and energy recovery units are being used to minimize energy waste. These innovations help reduce the overall energy footprint of cellulose fiber production.

Recycling and Biodegradability:

Recycling technologies, such as reverse osmosis and solvent extraction, are being used to recover valuable nutrients and fibers from post-consumer and post-industrial waste streams. Biodegradability refers to the ability of cellulose fibers to decompose naturally without causing harm to the environment. By promoting biodegradability, manufacturers can ensure that fibers return to the natural cycle once they reach the end of their lifecycle.

Nanotechnology:

Nanoparticles added to raw materials can improve the mechanical and thermal properties of the fibers, making them stronger and more durable. Nanotechnology can also help reduce the energy consumption of the production process by improving the efficiency of key operations. This not only enhances the quality of the final product but also contributes to a more sustainable production process.

Environmental Concerns and Future Prospects for Recycled Cellulose Fibers

Recycled cellulose fibers offer a promising solution to the environmental challenges of traditional production, but their adoption is still in its early stages due to several challenges.

Challenges:

The collection and sorting of waste fibers require significant infrastructure and labor investment, which can offset some of the environmental benefits. Recycled fibers often contain contaminants, such as plastics and other non-cellulose materials, which can degrade the performance of the final product. Removing these contaminants is a significant obstacle to widespread adoption.

Benefits:

Despite these challenges, the environmental benefits of using recycled cellulose fibers are substantial. They reduce the need for virgin fibers and associated environmental impacts, such as deforestation and pollution. Recycled fibers also promote a circular economy, where materials are reused and repurposed throughout their lifecycle. This creates a more sustainable and efficient production process.

Future Prospects:

Advancements in recycling technology, such as the use of enzymes and engineered enzymes, are making it easier to break down complex fibers into simpler components. These components can then be repurposed into a variety of products, from textiles to construction materials. The growing interest in sustainability is also driving innovation and investment in sustainable production methods. As these technologies continue to evolve, we can expect recycled cellulose fibers to become more prevalent in the market.

Role of Major Cellulose Fiber Manufacturers in Promoting Sustainability

Major manufacturers of cellulose fibers are playing a crucial role in promoting sustainability through corporate accountability, awareness campaigns, and regulatory compliance.

Corporate Sustainability Standards:

Manufacturers are adopting corporate sustainability standards, such as the Forest Stewardship Council (FSC) and the Forest Closing Standard (FCS), which provide guidelines for responsible forest management and certification. Adhering to these standards ensures that operations are environmentally sustainable and transparent.

Public Awareness Campaigns:

Awareness campaigns help educate consumers about the environmental benefits of cellulose fibers. These campaigns often highlight the role of manufacturers in reducing their environmental footprint and promoting sustainable practices. By raising consumer awareness, manufacturers can drive demand for more sustainable products.

Regulatory Compliance:

Manufacturers are working closely with regulators to ensure compliance with environmental regulations. They implement advanced technologies to reduce emissions and waste, and participate in environmental research and development to stay ahead of emerging challenges. By adhering to these regulations, manufacturers can enhance their reputation and competitiveness in the market.

Comparative Analysis of Cellulose Fiber vs Synthetic Fibers

Cellulose fiber and synthetic fibers are both widely used materials, each with its unique characteristics and environmental implications.

Environmental Footprint:

The production of synthetic fibers often involves the use of petroleum-based products, which have a high carbon footprint and contribute to air and water pollution. In contrast, cellulose fibers are derived from renewable resources and have a significantly lower environmental impact. This makes cellulose fibers a more sustainable choice for many applications.

Energy Consumption:

While synthetic fibers are often produced using less energy-intensive processes, the energy required to grow and process cellulose fibers is also relatively low compared to other materials like cotton or wool. This makes cellulose fibers a more efficient choice in terms of energy use.

Consumer Benefits:

Cellulose fibers are preferred for their softness, breathability, and natural appearance, making them ideal for use in textiles, furniture, and other products where comfort and aesthetics are important. They are also biodegradable and can be composted at the end of their lifecycle, reducing waste and pollution.

Applications:

Synthetic fibers excel in durability and resistance to environmental factors like mold and mildew, making them popular in industries where reliability and longevity are critical, such as construction and textiles. However, they come with their own set of environmental challenges, such as non-biodegradability and energy-intensive production processes.

Regulatory Environment and Standards for Sustainable Manufacturing

The regulatory environment surrounding the production of cellulose fibers is increasingly focused on promoting sustainability and environmental responsibility.

Regulatory Requirements:

Governments and regulatory bodies are implementing standards and policies to ensure that manufacturers adhere to environmental and labor protection regulations. For example, the European Union's Forest Products Directive (FPOD) sets standards for the sustainable production of wood-based products, including cellulose fibers. These regulations help ensure that cellulose fiber production meets high environmental standards.

Certifications and Standards:

Manufacturers are encouraged to adopt certifications and standards that demonstrate their commitment to sustainability, such as the Forest Stewardship Council (FSC) and the Forest Closing Standard (FCS). By obtaining these certifications, manufacturers can enhance their reputation and market competitiveness by proving their commitment to sustainable practices.

By adhering to these regulations and certifications, manufacturers can reduce their environmental impact and enhance their reputation and competitiveness in the market. This is particularly important given the growing demand for sustainable products and the increasing pressure from consumers and stakeholders to prioritize environmental responsibility.

+86 133 5816 4686

13358164686@163.com

Contact: COCO

Tel: +86 133 5816 4686

WhatsApp: +86 138 0714 0719

Add:

33 Huayuan Street, Wujin District, Changzhou City, Jiangsu Province