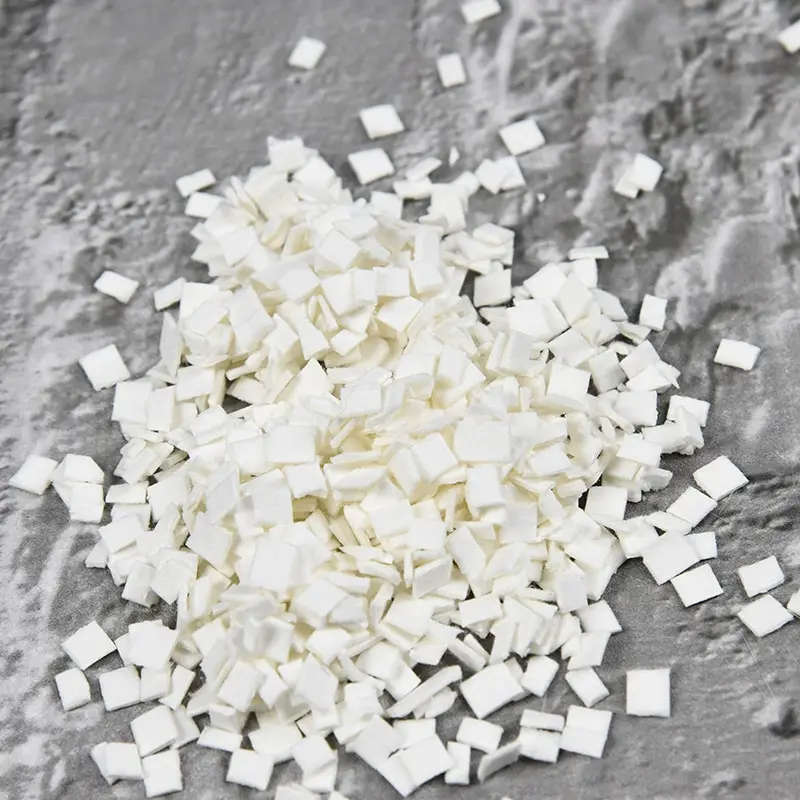

Cellulose Wood Fiber Innovates in Packaging

Cellulose wood fiber has emerged as a promising material for sustainable packaging solutions due to its biodegradability, renewability, and mechanical properties. The production of cellulose wood fiber involves sustainable practices such as closed-loop systems and energy-efficient technologies, which help reduce water usage and minimize waste. Certifications like the Forest Stewardship Council (FSC) and the International Sustainability and Carbon Certification (ISCC) ensure responsible forestry management and promote the sustainable sourcing of raw materials. Innovations in recycling methods, such as enzymatic treatments and mechanical recycling, have further enhanced the recyclability of cellulose wood fiber, allowing for the creation of high-quality products that can be reused multiple times. These advancements, combined with the biodegradable properties of cellulose wood fiber, which can be optimized under specific composting conditions, offer a comprehensive approach to sustainability in packaging.

Applications and Benefits of Cellulose Wood Fiber in Packaging

Here is a guide to the key applications and benefits of cellulose wood fiber in packaging, highlighting its versatile and sustainable potential:

- Biodegradability: Cellulose wood fiber offers a sustainable alternative to traditional plastics, reducing pollution and waste with a much lower environmental impact.

- Cost-effectiveness: Though initial costs might be higher due to sourcing and processing, cellulose wood fiber can lead to long-term savings and a positive brand image, making it a sound investment for manufacturers.

- Diverse Design Possibilities: Innovations in design, such as bi-layer and multi-layer structures, can enhance barrier properties and meet various packaging needs, from insulation to moisture protection.

- Advanced Manufacturing Techniques: Techniques like nano-sizing and surface treatments improve the strength and functional properties of cellulose wood fiber, enabling efficient large-scale production.

- Regulatory Alignment: As new regulations and certifications like FSC and PEFC push for sustainable sourcing, cellulose wood fiber is becoming a preferred material that meets stringent environmental and quality standards.

Sustainable Practices in Managing Cellulose Wood Fiber

Sustainable practices in managing cellulose wood fiber are critical for ensuring long-term environmental and economic benefits. Forest rotation periods play a crucial role in maintaining soil health and biodiversity, yet they must be balanced with the need for adequate wood supply. Innovative methods such as multifunctional forest management, which integrates timber production with conservation and recreation, offer promising solutions. Technological advancements like LiDAR, satellite imagery, and drones can further support sustainable practices by providing detailed and real-time data for optimizing harvesting and management plans. Blockchain and collaborative platforms enhance traceability and transparency in the supply chain, ensuring that sustainable practices are maintained from forest management to product delivery. Circular economy principles further enhance sustainability through recycling and reusing wood fiber products, reducing waste and extending resource life cycles. Integrating bio-based chemicals and materials derived from cellulose wood fiber into new product lines not only adds value but also aligns with the circular economy model. Additionally, the introduction of renewable energy sources, such as biomass and cogeneration systems, significantly reduces the carbon footprint of wood fiber production. These strategies collectively contribute to a more sustainable and efficient cellulose wood fiber industry.

Comparison of Cellulose Wood Fiber with Other Packaging Materials

When comparing cellulose wood fiber with other packaging materials, several key factors come into play:

- Cellulose Wood Fiber: Biodegradable and renewable, but may require higher production costs and potentially lower moisture resistance compared to plastics or paper.

- Plastics: Exceptional moisture resistance and lower production costs, yet come with significant environmental drawbacks such as non-biodegradability and higher carbon footprints.

- Paper: A sustainable and cost-effective alternative with good moisture resistance, but may not support the same structural integrity as cellulose wood fiber or plastics, especially in heavier packaging applications.

- Glass: Offers high durability and recyclability but is more susceptible to breakage and significantly heavier than cellulose wood fiber, plastics, or paper.

- Metal: Provides excellent protection and recycling capabilities, but its production is energy-intensive and adds significant weight to packaging designs.

Each material brings its own set of advantages and challenges, making the choice of packaging material highly context-dependent on factors like environmental impact, cost, and the specific needs of the product.

Ecological Benefits and Drawbacks of Cellulose Wood Fiber in Packaging

Here is a concise overview of the ecological benefits and drawbacks of cellulose wood fiber in packaging:

- Ecological Benefits:

- Biodegradability: Cellulose wood fibers naturally break down, reducing landfill waste.

- Sustainably Sourced Options: Promote reforestation and biodiversity, and forest management certifications like FSC ensure responsible harvesting practices.

- Water Absorption:

- Hydrophobic Coatings: Enhance moisture resistance, preventing degradation and maintaining product quality. Careful packaging and storage are required to avoid moisture exposure.

- Microbiological Activity:

- Antimicrobial Treatments: Extend the shelf life of products by inhibiting fungi and bacteria growth, crucial for protecting food and pharmaceutical items.

- Raw Material Sustainability:

- Derived from Virgin Wood Pulp and Recycled Sources: Cellulose wood fibers can be sourced from both virgin wood pulp and recycled materials, reducing the need for virgin materials and supporting waste reduction.

- Supply Chain Challenges:

- Ensuring Consistent Quality and Traceability: Critical to maintain sustainable practices. Standardized protocols and transparent manufacturing processes help mitigate these issues.

This version of the article is streamlined, with each section clearly defined and the content refined for clarity and professionalism.

+86 133 5816 4686

13358164686@163.com

Contact: COCO

Tel: +86 133 5816 4686

WhatsApp: +86 138 0714 0719

Add:

33 Huayuan Street, Wujin District, Changzhou City, Jiangsu Province